FAQs

Can the choice of centralizers contribute to minimizing casing wear?

Yes! Centralizers reduce wear on the casing by promoting proper centralization, minimizing contact between the casing and the wellbore wall, enhancing cement coverage, distributing weight and pressure evenly, facilitating fluid movement, and improving overall wellbore stability. By optimizing casing support and positioning, centralizers play a critical role in extending the operational life of the casing and ensuring the integrity of oil and gas wells.

Bow-spring centralizers, with their flexible design and high restoring force, are particularly effective in enhancing cement coverage by conforming to irregularities in the wellbore and ensuring consistent standoff. Solid body centralizers offer enhanced stability and durability, making them ideal for vertical or mildly deviated wellbores where casing rotation is limited. Read more...

Should I invest in casing with anti-corrosive coating?

While anti-corrosive casing coatings and cement sheaths both offer corrosion protection, anti-corrosive coatings alone are insufficient to safeguard casing and will not outperform a full cement sheaths in protecting against corrosion. The comprehensive benefits of a full cement sheath underscores its superiority in ensuring long-term casing integrity and wellbore protection. Learn more...

What do you recommend on Chrome tubulars, (CRA's or Chrome Running Assemblies)?

When using CRA or chrome tubulars, a key concern is whether centralizers might accelerate corrosion. In fact, the opposite is true: in most cases, the centralizer (typically made from a less noble steel) will corrode first, acting as a sacrificial anode and offering protection to the more corrosion-resistant tubular.

It's also important to consider stop collar attachment methods, as intrusive options like screws can create stress corrosion risks—but there are ways to mitigate this. Read the full details here...

What are the risks of using polymer centralizers?

Many polymer centralizers, while advantageous in some respects, can present significant risks if they break or wear down during casing running operations. Their material composition, while non-corrosive, is often not up to challenging wellbore conditions. Learn more...

Why should I trust the data provided on Centek datasheets?

We prioritize transparent testing processes, so customers can be assured that the centralizers they choose will perform as expected, even in the most challenging well conditions. We also conduct rigorous testing in various scenarios to ensure our products can withstand high levels of stress, pressure, and friction, and we have strict quality control protocols in place throughout the production cycle. Read our article on the importance of verifying data sources when selecting centralizer supplier.

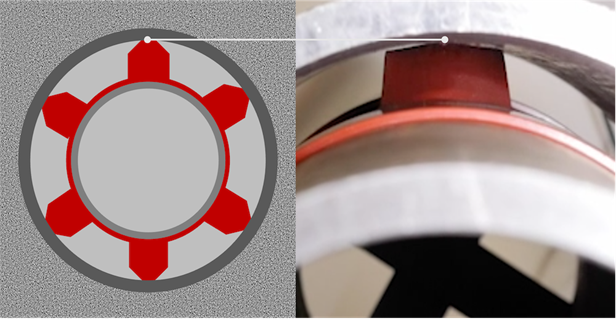

How do made-to-gauge single piece centralizers improve mud removal?

Centralizers play a critical role in the efficiency of mud removal and cementing operations by keeping the casing centralized in the wellbore. This allows for a more uniform annular space, which facilitates the displacement of drilling mud and even distribution of cement slurry. Made-to-gauge single-piece centralizers, specifically designed for these well conditions, offer significant advantages over conventional centralizers in improving mud removal. Learn more...

How is differential sticking reduced through proper centralization?

Centralizers play a crucial role in mitigating the occurrence of differential sticking by promoting optimal wellbore geometry and reducing the risk of pipe contact with the formation. By ensuring proper centralization of the casing within the wellbore, centralizers help maintain consistent standoff between the pipe and the formation wall, minimizing the potential for differential pressure build-up and sticking. Learn more...

Do single piece centralizer have improved flow by area?

As well as increasing flow by area, Centek made to gauge bow spring centralizers maximize standoff and limit well bore interaction. Whilst, solid centralizers run in hole under gauge and limit standoff and their profile, inflexibility and interaction with the wellbore can increase torque and drag and can damage filter cake. Learn more...

Are all Centek single piece bow spring centralizers heat treated?

Yes! Learn more about our proprietary heat treatment process here.

Can centralizers reduce wear on casing?

Yes! Centralizers reduce wear on the casing by promoting proper centralization, minimizing contact between the casing and the wellbore wall, enhancing cement coverage, distributing weight and pressure evenly, facilitating fluid movement, and improving overall wellbore stability. By optimizing casing support and positioning, centralizers play a critical role in extending the operational life of the casing and ensuring the integrity of oil and gas wells. Learn more...

Can Centek S2 single piece bow spring centralizer travel through a restriction?

Can Centek S2 single piece bow spring centralizer travel through a tight spot?

Although designed for gauge applications, the S2 is engineered with the flexibility to run through tight spots. This flexibility mitigates increased running forces. Talk to a sales advisor to discuss the options available

Can Centek S2 centralizers travel through a FMS?

Although designed for gauge applications, the S2 is able to be run through FMS without damage. This is due to its highly flexible bows. Talk to a sales advisor to discuss the options available

Can you use Centek stop collars with non-Centek centralizers and Centek centralizer with non-Centek stop collars?

Our products are developed to work in conjunction with each other and we are unable to guarantee the performance of either our stop collars or centralizers with another company's products. In the event of an issue we would be unable to ascertain which product was at fault.

Our extremely tight production tolerances ensure our products are manufactured to fit snuggly over the casing. Lower quality competitor products require a larger clearance fit due to their ovality. This adds the risk of the competitor stop collar riding over the Centek centralizer. Traveling through tight spots, high inclinations and tortuous well paths can prevent the centralizer from rotating as designed, causing the potential for downhole issues and costly delays. Add in any ovality in the casing string and the problem is compounded

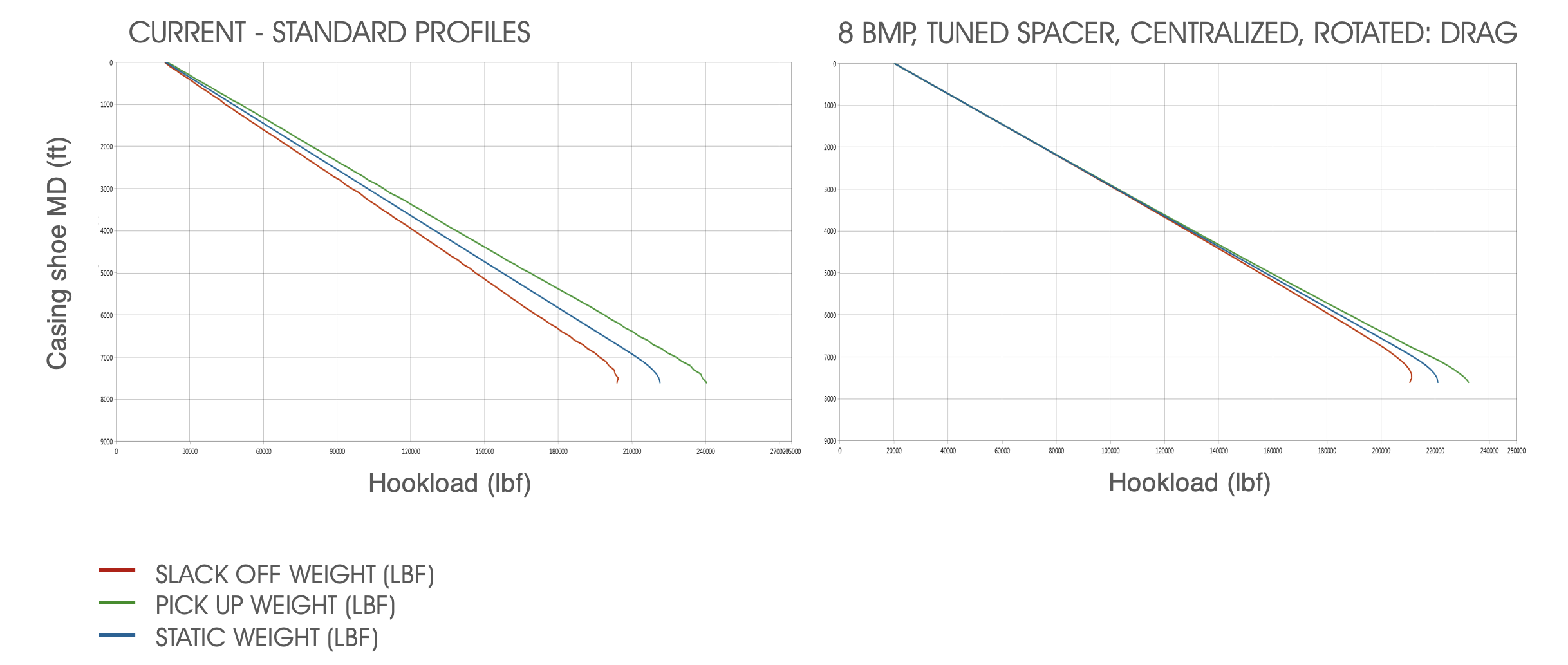

Does adding more centralizers to the string increase drag?

No...not with our flexible single piece centralizers. In fact up to a point the more centralizers you use the lower the drag. Learn more...

Can I rotate with Centek single piece bow spring centralizer?

Absolutely! Centek single piece bow spring centralizers are strong enough to stand up to the rotational torque of casing rotation and have a low enough coefficient of friction to allow the casing to rotate freely inside the centralizers. Here the centralizer is acting as a sleeve bearing. Read more...

Can I use a Centek single piece bow spring centralizer in ERD wells?

Extended-reach drilling (ERD) wells are becoming more common in the industry in order to produce reservoirs in a more economical way. However, there are numerous challenges associated with design and construction of these wells, such as directional drilling optimization, equivalent circulation density (ECD) limitations, and casing running issues. Centek premium single piece, bow spring centralizers are developed to perform in ERD wells. This is due to their inherent strength and engineered flexibility. Read more...

Do all centralizer manufacturers test their products in the same way?

The short answer is 'no'. Even with API 10D regulations, we know competitors do not test in the same way. This will be exacerbated by the removal of the monogram programme by the API. We can tell you that in our side by side comparison testing, on our own S2 product and competitor products targeted at the same applications, the results were conclusive, highlighting the superior performance of the S2. Testing also indicated that many competitor products did not perform to the claims of their datasheets. See the test results...

Can I rotate casing with the tight tolerance single piece bow spring centralizers?

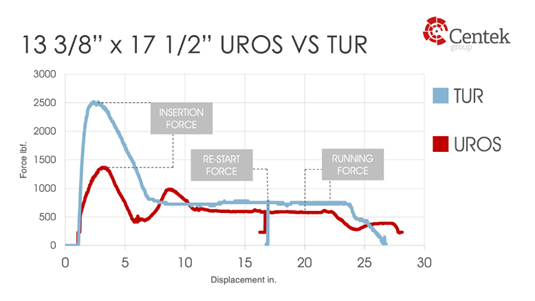

Yes, TUR and UROS centralizers are designed to allow rotation of the string, even when fully compressed. We have case studies which prove this.

Are Centek tight tolerance single piece bow spring centralizers built to last if the casing needs to be pushed in the well?

UROS and TURs are tight tolerance centralizers which means they have a high flexibility rating compared with the regular bows springs, so 'yes', they are designed to be pushed.

Why is it important to use the recommended quantity of centralizers?

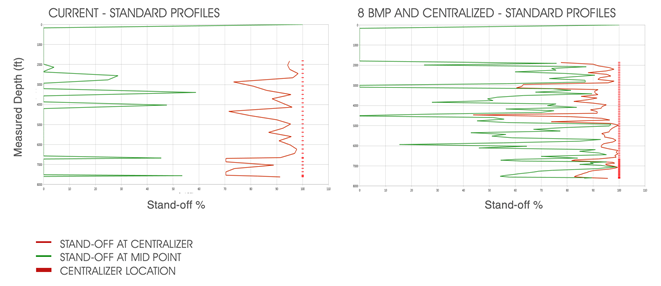

Our simulation software accurately predicts the quantity of centralizers needed to achieve the desired stand-off. Deviation from this can dramatically reduce the stand-off, often to below the API performance standard.

How does drag compare between the UROS and the TUR?

How does drag compare between the UROS and the TUR?

The drag force with the UROS will be reduced compared with the TUR. In the following chart, the difference can be seen between the axial load required to pass through the same restriction.

What does restoring force mean?

Restoring force is the force required to suspend the pipe and push it away for the casing or wellbore wall. Centek bow spring centralizers have high restoring forces due to the steel used, our unique manufacturing process and innovative heat treatment process.

What does stand-off mean?

The term stand-off (SO) describes the extent to which the pipe is centered, A standoff of 0% means that the pipe touches the wellbore. Regardless of the centralizer type, the goal is to provide a positive standoff, preferably above 67%, throughout the casing string. Stand-off can be predicted using our proprietary Latload system.

What are start and running forces?

Starting force is the force required to displace the centralizer through a restriction and can drastically change based on how the centralizer is held on the pipe. Running force is the force required to displace the centralizer inside of a restriction once it is compressed. Many of our products have zero or low start and running forces.

What is the chordal drop on a Centek single piece centralizer?

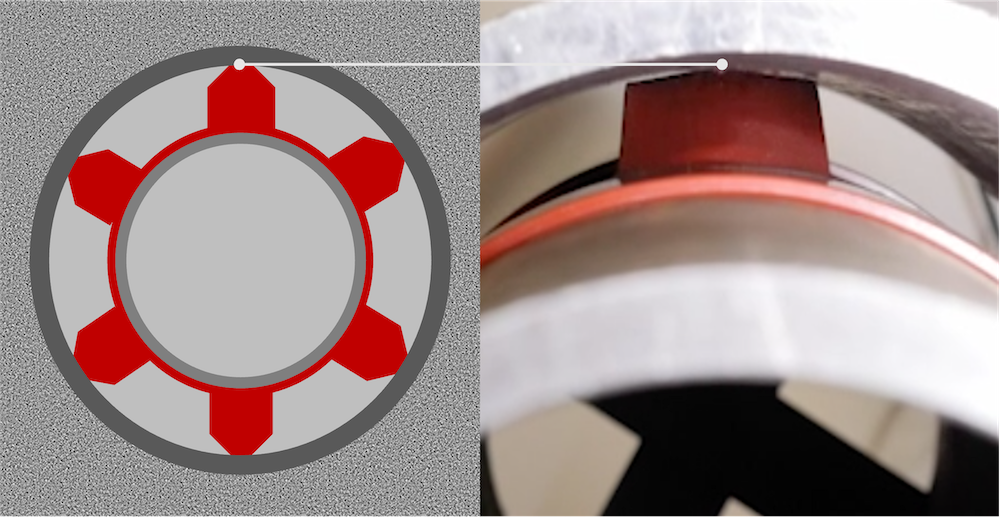

The chordal drop is a cross curvature added to each bow on many of the single piece centralizers in our bow spring range. This reduces the contact area with the wellbore walls, easing run-in-hole (RIH)

Where are Centek products manufactured?

We have manufacturing plants in USA, UK and China. Find out more...

How do I purchase a Centek product?

Our products are only available through our network for distributors. For more information contact sales@centekgroup.com or find a distributor using our Distributor Finder