NEWS The Importance of Flow-by Area in Cementing Operations

Flow-by Area—the space through which fluids like drilling mud and cement flow within the annular space—is critical to ensuring successful cementing in oil and gas well cementing operations. Efficient fluid dynamics are key to achieving proper mud displacement, well clean out and cement placement, which directly impact well integrity and long-term production. It is widely accepted in the industry that improved annular Flow-by Area leads to higher primary cementing success. This is where the role of well-engineered centralizers, particularly Centek single-piece centralizers, becomes crucial.

Why Flow-by Area Matters

Flow By Area directly affects the displacement efficiency of fluids in the annulus, which governs principal factors such as:

- Fluid Properties: The viscosity, density, and rheology of both drilling mud and cement determine how they flow through the annulus.

- Flow Regimes: Laminar or turbulent flow regimes impact the effectiveness of mud removal and the subsequent placement of cement.

- Pipe Centralization: Proper centralization ensures that the annulus maintains consistent fluid flow without forming narrow sections or dead spots, where fluids can fail to penetrate resulting in channelling.

- ECD Constraints: Effective Flow-by Area management can prevent excessive Equivalent Circulating Density (ECD), helping to avoid fracturing weak formations.

- Standoff: Proper standoff, or the space between the casing and wellbore, ensures an unobstructed flow path for fluids, enabling efficient displacement and cementation.

These factors collectively influence cementing outcomes, leading to improved well cleanout, cementation performance, well longevity, and pipe movement. However, a key consideration is how fluid dynamics in the annulus influence the effectiveness of these operations.

Fluid Dynamics in Cementing and Mud Displacement

The fluid dynamics of both drilling mud and cement play a critical role in successful well cementing operations. Two key fluid regimes—laminar and turbulent flow—govern the movement of these fluids through the annulus, directly impacting their ability to remove mud and create an effective seal with cement.

- Drilling Mud Displacement: Drilling mud needs to be effectively displaced to ensure clean cement bonding with the wellbore. If the mud remains in place, it can lead to channelling, a common issue that compromises cementing integrity. Efficient Flow-by Area enhances fluid velocity, which helps create turbulent flow. In turbulent flow, fluids move in irregular patterns, which is more effective in displacing the mud from the annulus.

- Cement Placement: The rheology of cement, including its viscosity and density, affects its ability to fill the annulus evenly. Optimized Flow-by Area allows for a uniform fluid path, which helps in avoiding cement slumping or settling, particularly in horizontal or inclined wells. Higher fluid velocities achieved through enhanced Flow-by Area improve the displacement of mud, allowing for more complete and effective cementation.

The Role of Centek Single-Piece Centralizers

One of the biggest factors affecting annular fluid dynamics is the design of the centralizer. Traditional solid centralizers, while capable of centralizing the casing, often reduce the annular space and create flow restrictions, limiting the effectiveness of mud removal and cement placement. These restrictions lead to low side conditions, where fluids can’t flow efficiently, creating areas of poor cement coverage.

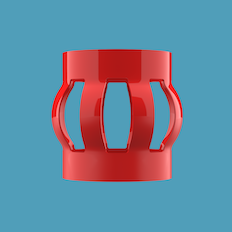

Centek’s single-piece centralizers, such as the Centek S2 Centralizer, are specifically designed to maximize Flow-by Area by ensuring greater standoff and reducing flow restrictions. This leads to significant improvements in fluid dynamics for both mud and cement:

- Enhanced Fluid Velocity: By providing a larger, more consistent annular space, Centek centralizers allow for greater fluid velocity. This improvement helps to establish turbulent flow regimes, which are critical for cleaning out the wellbore and displacing mud effectively.

- Reduced Low-Side Conditions: The single-piece design of Centek centralizers ensures uniform standoff, minimizing low-side conditions where fluid velocity slows, and mud or cement can stagnate. This uniform fluid path is critical in maintaining the proper flow dynamics needed for complete cementation.

- Improved Pipe Movement: The smooth, continuous shape of the Centek centralizers allows for better pipe movement during operations, which further supports even fluid distribution and optimal cement placement.

Impact on Cementing Operations

Optimized fluid dynamics achieved through enhanced Flow-by Area lead to several well-documented benefits during cementing operations:

- Better Mud Removal: Increased fluid velocity through a larger annular space ensures more complete mud displacement. Without adequate mud removal, cement placement can be compromised, leading to potential weak points in the cement sheath.

- More Uniform Cementing: With the annular space optimized, the cement can flow more evenly, reducing the risk of voids or channels that might weaken the cement bond.

- Reduced ECD Risks: By maximizing Flow-by Area, Centek centralizers help manage ECD constraints, ensuring pressure is maintained at safe levels, especially in fragile formations.

- Improved Long-Term Well Integrity: Proper cement placement ensures zonal isolation, reduces the risk of gas migration, and prevents corrosion, contributing to the overall health and longevity of the well.

Conclusion

Fluid dynamics, particularly in the form of Flow-by Area, is essential for successful cementing operations in oil and gas wells. Centek’s single-piece centralizers, by enhancing annular Flow-by Area, significantly improve fluid velocity, ensure proper mud displacement, and lead to better cementation results. In contrast to traditional solid centralizers, Centek’s engineered design optimizes the fluid path, allowing operators to achieve superior cementing outcomes and improved long-term well integrity.

In short, choosing Centek centralizers can result in more efficient operations, fewer cementing issues, and a longer well life—making them a crucial investment for any well.

PRODUCTS USEDS2 Bow Spring Centralizer

Engineered for both high strength and flexibility, the patented S2 is a premium single piece bow spring centralizer developed for challenging wellbores

PRODUCTS USEDOBS Bow Spring Centralizer

The Centek OBS is a low-cost, one piece, bow spring centralizer manufactured to provide high restoring forces and excellent standoff in onshore wells